Product

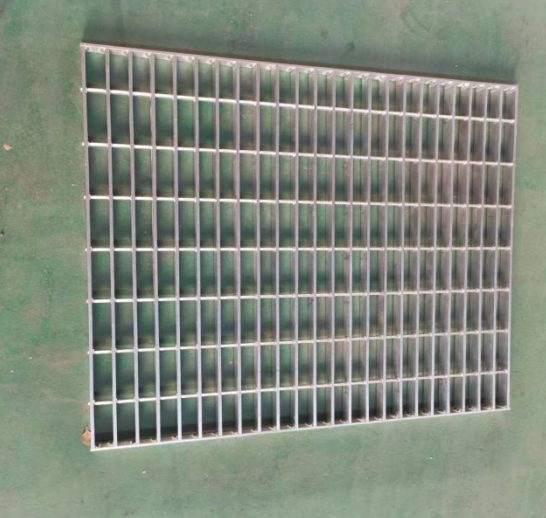

Aluminum grille

In order to adapt to different use environments, aluminum grilles have been developed on the basis of steel gratings. Aluminum grilles have been adopted in many cutting-edge projects, providing unique and diverse design elements, and the application of aluminum grilles can be perfectly integrated into the overall design of the building.

Keyword:

sheet metal

Category:

Aluminum grille

In order to adapt to different use environments, aluminum grilles have been developed on the basis of steel gratings. Aluminum grilles have been adopted in many cutting-edge projects, providing unique and diverse design elements, and the application of aluminum grilles can be perfectly integrated into the overall design of the building.

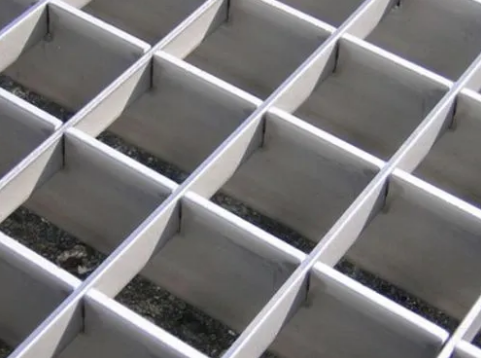

Aluminum grille manufacturing process

The aluminum grille is pressed by an advanced aluminum press, which penetrates the connecting square rod into the neatly arranged bearing flat aluminum, and presses and deforms the square rod through the aluminum press, so as to fix and lock the bearing flat aluminum to form a complete and solid mesh grid structure

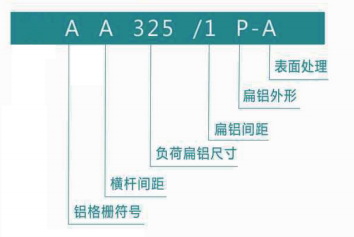

Naming conventions

Code description

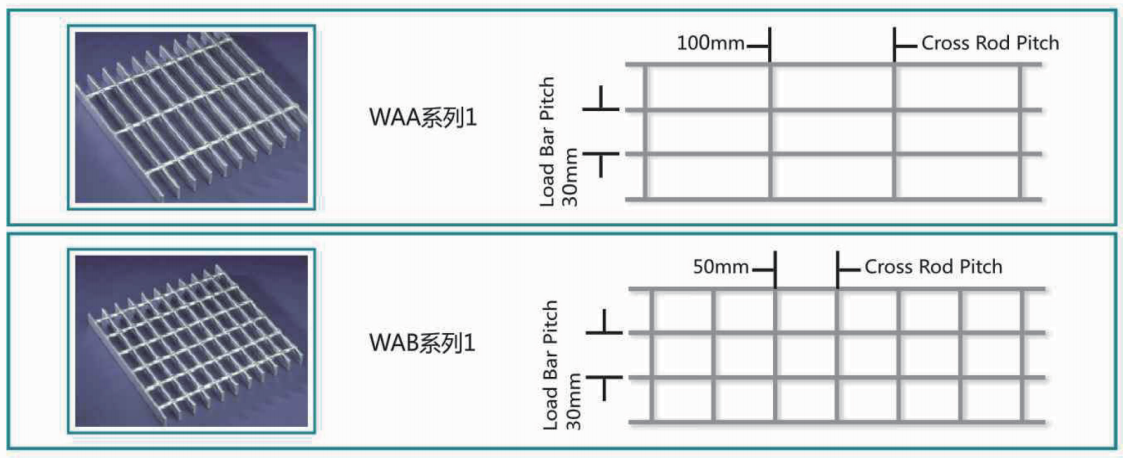

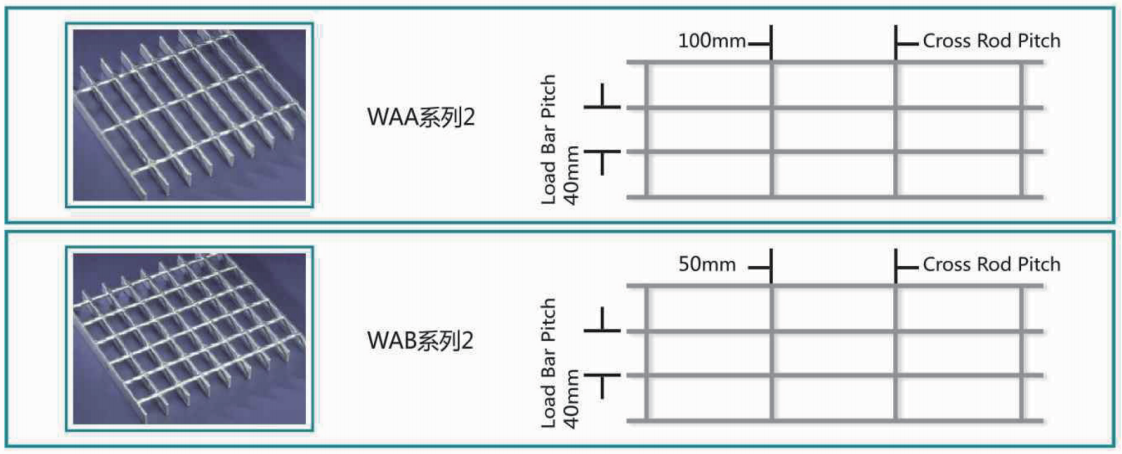

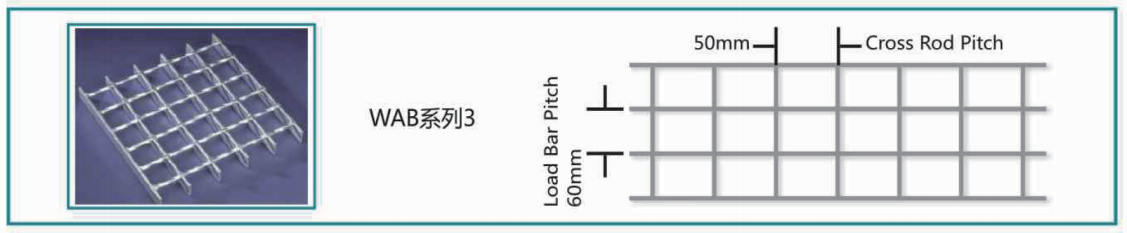

| Crossbar spacing | A 100mm(center spacing) B 50mm(center spacing) |

| Flat aluminum size | Commonly used 25*3 to 65*5 and other specifications |

| Flat aluminum spacing |

Series 1 30mm (center distance) Series 2 40mm (center distance) Series 3 60mm() |

The material

is recommended for use in environments where lightweight materials and appearance requirements are high. The material is aluminum: 6063-T6

In

order to improve the anti-slip performance, steel gratings and aluminum grilles can be set up with tread plates to increase their anti-slip ability on sloped walkways.

| P | Planar type |

| S | Zigzag |

| G | Fine gravel attached |

| R | With raised pattern |

Surface treatment

| A | Anodizing |

| P | Dipped paint |

| In the | Not processed |

Aluminum grille model series

Series 1

This series of aluminum grille conforms to AS1657 standard, can be applied to fixed platforms, walkways, stairs or escalators, is the most widely used product in the grille industry load flat aluminum center spacing of 30mm, with the best strength and impact resistance, widely used in power plants, fine chemicals, sewage treatment plants, chemical plants and stair steps. The toothed aluminum grille has good anti-slip performance and is mostly used in offshore platforms with more oil pollution.

*Series 2

is more economical and lightweight than Series 1, and the center spacing of the loaded flat aluminum is 2mm, which meets the standard requirements of AS40. The product is often used where light loads and shocks are light.

*Series 3 Series 3

Aluminum Grille is specially developed for the mining industry, with a center spacing of 60mm for the load flat aluminum, which solves the problem of mineral accumulation on the walkway after splashing, and is commonly used in mineral mining and processing engineering.

Aluminum Grille Selection

Aluminum grilles can be adapted to many applications, see the selection table below

Selection under light load Maximum span recommendation (for service platforms with fewer pedestrians)

| Load flat aluminum size | Average load = 3kPa Deflection = 5mm | ||

| Series 1 | Series 2 | Series 3 | |

| 25x3 | 1044 | 974 | 878 |

| 25x5 | 1187 | 1107 | 998 |

| 32x3 | 1257 | 1172 | 1057 |

| 32x5 | 1428 | 1332 | 1201 |

| 40x3 | 1486 | 1386 | 1249 |

| 40x5 | 1688 | 1575 | 1420 |

| 45x5 | 1844 | 1720 | 1551 |

| 50x5 | 1996 | 1862 | 1678 |

| 55x5 | 2144 | 2000 | 1803 |

| 65x5 | 2430 | 2267 | 2043 |

Selection under medium load Maximum span recommendation (for pedestrian-intensive platforms)

| Load flat aluminum size | Average load = 4kPa Deflection = 5mm | ||

| Series 1 | Series 2 | Series 3 | |

| 25x3 | 972 | 907 | 817 |

| 25x5 | 1104 | 1030 | 929 |

| 32x3 | 1170 | 1091 | 984 |

| 32x5 | 1329 | 1240 | 1118 |

| 40x3 | 1383 | 1290 | 1163 |

| 40x5 | 1571 | 1466 | 1321 |

| 45x5 | 1716 | 1601 | 1443 |

| 50x5 | 1857 | 1732 | 1562 |

| 55x5 | 1995 | 1861 | 1678 |

| 65x5 | 2261 | 2109 | 1901 |

Related products

Online Message