Product

Grating

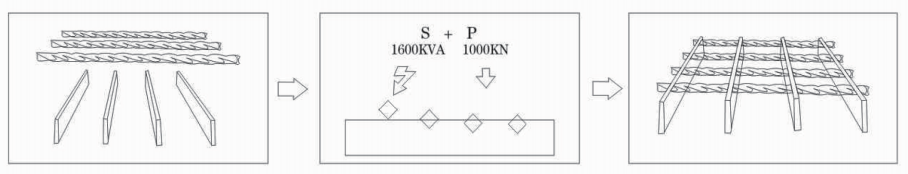

Steel grating is made of the world's most advanced, PLC-controlled high-voltage pressure resistance welding machine, the manipulator automatically puts the crossbar (twisted square steel or round rod, the same below) horizontally on the evenly arranged flat steel, through the strong 1600KVA electric welding power and 1000KN hydraulic pressure to weld the crossbar pressure into the flat steel, so as to obtain the steel grating with strong solder joints, stability and strength.

Keyword:

sheet metal

Category:

Aluminum grille

Manufacturing process of steel grating

Steel grating is made of the world's most advanced, PLC-controlled high-voltage pressure resistance welding machine, the manipulator automatically puts the crossbar (twisted square steel or round rod, the same below) horizontally on the evenly arranged flat steel, through the strong 1600KVA electric welding power and 1000KN hydraulic pressure to weld the crossbar pressure into the flat steel, so as to obtain the steel grating with strong solder joints, stability and strength.

The superiority of steel gratings

Compared with patterned steel plates and other grilles, series steel gratings have the following advantages: * Material saving:

the most material-saving way to withstand the same load conditions, correspondingly, can reduce the material of the red structure.

* Reduce investment: save materials, save labor, save construction period, free cleaning and maintenance.

* Easy construction: bolted on the pre-installed support, one person can complete.

* Save construction period: the product does not need to be reprocessed on site, and the installation is very fast.

* Durable: the surface is treated with hot-dip zinc anti-corrosion, which has strong impact resistance and heavy pressure resistance.

* Modern style: beautiful shape, design standard, ventilation and light, giving people an overall smooth modern feeling.

* Light structure: less wood, light structure, and easy to lift.

* Anti-dirt: No accumulation of rain, ice and dust.

* Reduce wind resistance: due to good ventilation, small wind resistance in case of large winds, reduce wind damage.

* Convenient design: no need for small support beams as supports to bear loads, simplified design; Without the need for the customer to design the steel grating detail, Metro optimizes the layout on behalf of the customer according to the customer's structure drawing.

Manufacturing process of steel grating

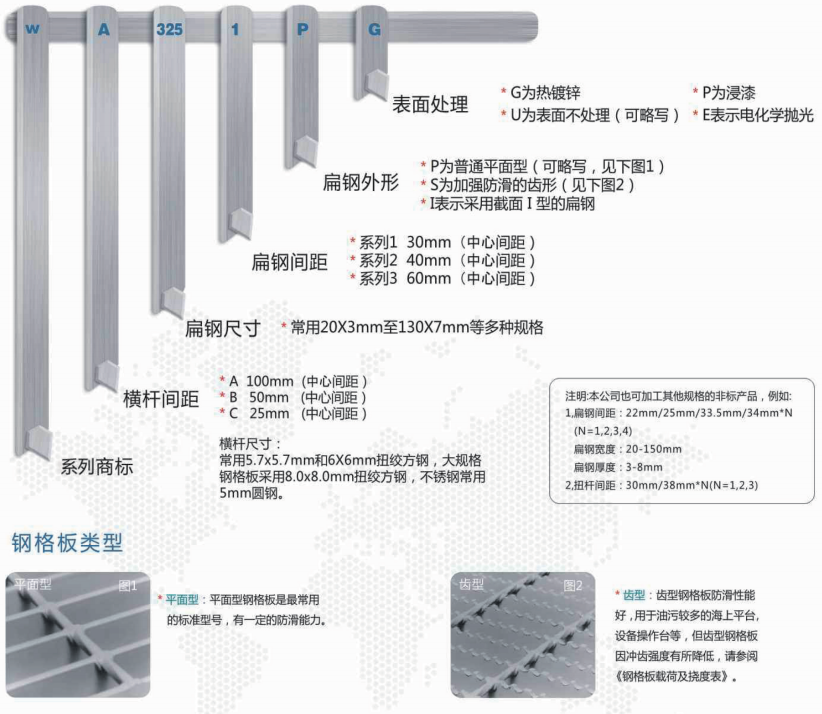

Naming conventions

Execution standards

Steel grating standard: China YB/T4001.1-2007

Production can also be organized according to foreign or other standards according to the agreement between supply and demand. Such as British standard BS4592:2006, American standard ANSI/NAAMMMBG531-09, German standard DIN24537-1:2006 Australian standard AS1657-1992 and other steel standards: China GB700-2006GB1220-92

can also be organized according to foreign or other standards according to the agreement between supply and demand. Such as European standard EN10025-2, American standard ASTMA1011, etc. Hot-dip galvanizing standard: China GB/T13912-2002

can also be organized according to foreign or other standards according to the agreement between supply and demand. Such as American standard ASTMA123, European standard, BSENISO1461, Australian standard AS4680, etc.

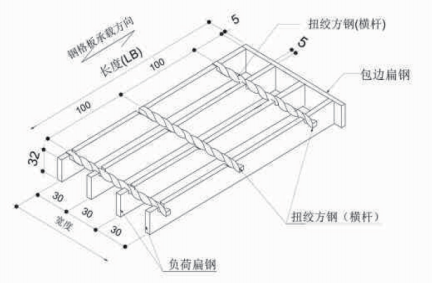

Explanation of terms

|

【Load flat bar】Flat steel that mainly bears the load [crossbar] twisted square steel or round rod connecting the load flat steel 【Hemmed flat steel】A flat steel that connects the two ends or notches of the load flat steel 【Bearing direction】Along the direction of the load flat steel arrangement, it is agreed to be the bearing direction of the steel grating, usually indicated by the arrow "⇋" symbol. |

|

Steel grating model series

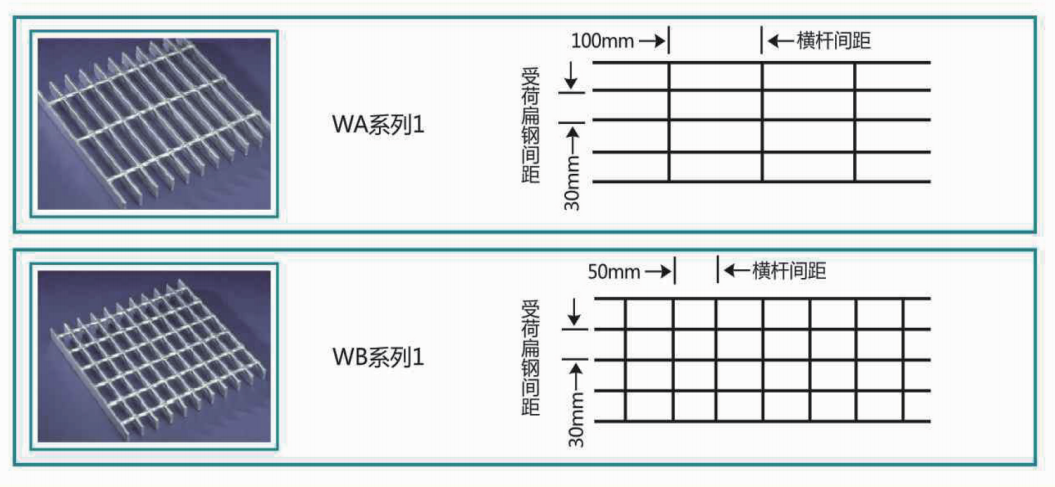

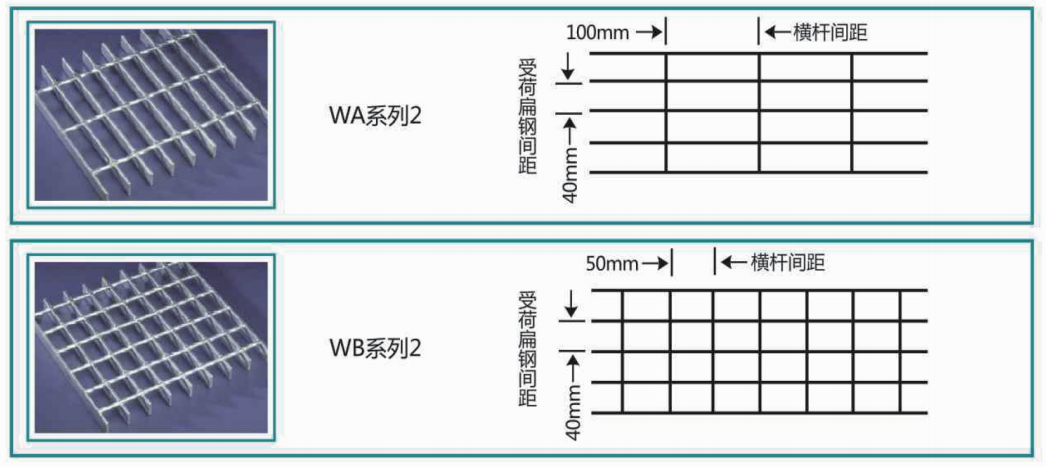

*Series 1

This series is a common model of steel grating, the center spacing of the loaded flat steel is 30mm, in line with the standards of the United States, Australia, Japan and other countries. This series of flat bars is the densest and strongest, making it suitable for a variety of uses.

*Series 2

This series is an economical and lightweight model of steel grating, with a 40mm E squint between the centers of the loaded flat steel. It meets the specifications of fixed platforms, walkways and stair steps set by standards such as ®the United Kingdom, Germany, France and Japan. Commonly used in belt corridors, warehouse shelves, trestle bridges, protective fences and awning grills.

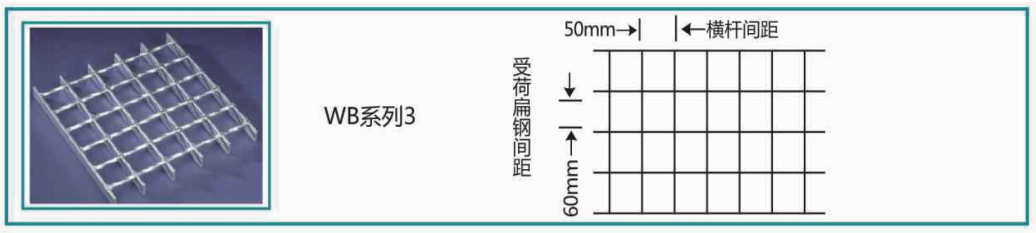

*Series 3

This series of steel gratings is specially developed for the mining industry and has a center spacing of 60 mm for load-bearing flat steel. It solves the problem of mineral splashing on the aisle, and is commonly used in mineral mining and processing projects. Due to its material saving, this series of steel grating is also the best choice for suspended ceilings in buildings.

* Grid plate edging welding for series welding series 1: one welding

for every five strips; Series 2: one for every four welds; Series 3: One weld for every three strips.

Steel grating selection

In addition to the models recommended in the table below, other specifications of steel grating can also be designed, depending on the customer's order quantity and delivery time. The force parameters of stainless steel grating can refer to the safety load and deflection table of carbon steel grating.

Light and medium loads Maximum recommended span (unit: mm)

| Load flat steel size | The average load of the platform for maintenance = 2.5KPA |

For platforms with few pedestrians Average load = 3KPA | For platforms with dense pedestrians Uniform load = 4KPA | ||||||

| Deflection = 4mm | Deflection = 4mm | Deflection = 4mm | |||||||

| Unit(mm) | Series 1 | Series 2 | Series 3 | Series 1 | Series 2 | Series 3 | Series 1 | Series 2 | Series 3 |

| 20x3 | 1110 | 1030 | 940 | 1060 | 990 | 900 | 990 | 930 | 840 |

| 25x3 | 1310 | 1210 | 1110 | 1250 | 1170 | 1060 | 1170 | 1090 | 990 |

| 32x3 | 1560 | 1470 | 1330 | 1500 | 1410 | 1270 | 1410 | 1320 | 1190 |

| 40x3 | 1840 | 1720 | 1570 | 1770 | 1650 | 1500 | 1660 | 1550 | 1400 |

| 20x5 | 1250 | 1170 | 1060 | 1200 | 1120 | 1020 | 1120 | 1050 | 950 |

| 25x5 | 1470 | 1360 | 1250 | 1410 | 1310 | 1200 | 1320 | 1230 | 1120 |

| 32x5 | 1750 | 1650 | 1500 | 1680 | 1590 | 1440 | 1580 | 1490 | 1350 |

| 40x5 | 2050 | 1930 | 1760 | 1970 | 1850 | 1690 | 1860 | 1740 | 1590 |

| 45x5 | 2220 | 2100 | 1920 | 2150 | 2020 | 1840 | 2020 | 1900 | 1730 |

| 50x5 | 2390 | 2260 | 2070 | 2310 | 2180 | 1990 | 2180 | 2050 | 1870 |

| 55x5 | 2560 | 2410 | 2210 | 2470 | 2330 | 2130 | 2340 | 2190 | 2000 |

| 65x5 | 2870 | 2710 | 2490 | 2770 | 2620 | 2400 | 2620 | 2470 | 2260 |

| 75x5 | 3170 | 2990 | 2760 | 3070 | 2890 | 2660 | 2910 | 2730 | 2500 |

| 75x6 | 3270 | 3090 | 2860 | 3170 | 3000 | 2760 | 3010 | 2840 | 2600 |

Heavy duty Maximum recommended span (in mm)

| Load flat steel size | - General factories and workshops, motor rooms, trolleys pass | - General heavy load area, boiler equipment and heavy equipment area | ||||

| Average load = 5kPa | Average load = 7.5kPa | |||||

| Deflection = 4mm | Deflection = 4mm | |||||

| Unit (mm) | Series 1 | Series 2 | Series 3 | Series 1 | Series 2 | Series 3 |

| 20x3 | 940 | 880 | 790 | 850 | 800 | 720 |

| 25x3 | 1110 | 1030 | 940 | 1010 | 940 | 850 |

| 32x3 | 1330 | 1250 | 1130 | 1210 | 1130 | 1020 |

| 40x3 | 1570 | 1470 | 1330 | 1430 | 1330 | 1210 |

| 20x5 | 1070 | 990 | 900 | 970 | 900 | 820 |

| 25x5 | 1260 | 1170 | 1060 | 1140 | 1060 | 960 |

| 32x5 | 1500 | 1410 | 1280 | 1370 | 1280 | 1160 |

| 40x5 | 1770 | 1660 | 1510 | 1610 | 1510 | 1370 |

| 45x5 | 1930 | 1810 | 1640 | 1760 | 1650 | 1490 |

| 50x5 | 2080 | 1950 | 1780 | 1900 | 1780 | 1620 |

| 55x5 | 2230 | 2090 | 1900 | 2040 | 1910 | 1730 |

| 65x5 | 2510 | 2360 | 2150 | 2300 | 2150 | 1960 |

| 75x5 | 2780 | 2610 | 2380 | 2550 | 2390 | 2180 |

| 75x6 | 2880 | 2710 | 2480 | 2660 | 2490 | 2270 |

Related products

Online Message