Product

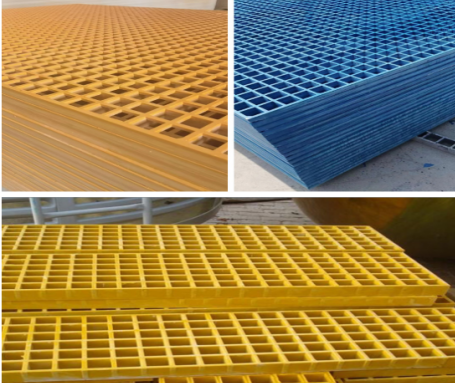

Frp grating

The FRP Grille (FRP) is a modular, fiber-reinforced plastic grid. It is available in standard sizes or can be cut to customer-specified sizes.The horizontal and vertical cross structure design can effectively disperse the force, so the FRP grille designed in the shape of the block provides excellent bearing capacity.

Keyword:

sheet metal

Category:

Aluminum grille

The FRP Grille (FRP) is a modular, fiber-reinforced plastic grid. It is available in standard sizes or can be cut to customer-specified sizes.

The horizontal and vertical cross structure design can effectively disperse the force, so the FRP grille designed in the shape of the block provides excellent bearing capacity.

High-density fiber material provides maximum corrosion protection against many BE environments with a variety of chemical °FRP

available in standard sizes of 1220 x 3660 mm.

Performance characteristics

* integrated molding design structure improves the bearing capacity * cross-designed bearing structure, disperses the force, and greatly improves the bearing capacity.

* The surface is smooth and rich in oil, and it is not easy to adhere to dirt.

* Fine glass fibers and polycool resin are tightly intertwined to provide excellent corrosion resistance.

* 70% of the cutout area.

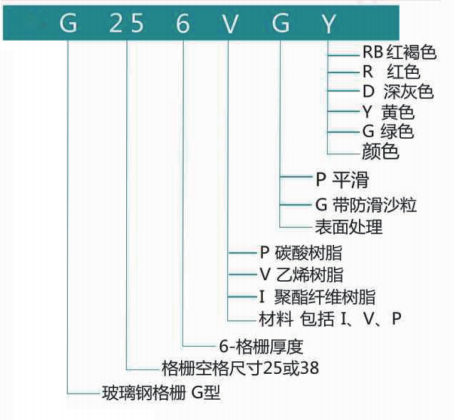

Naming conventions

Material

I polyfiber resin meets ASTM (American Society for Testing and Materials) E-84 standard fire rating class 1, index 25 or lower

V vinyl resin

meets ASTM (American Society for Testing and Materials)-84 standard, fire class 1, Index 25 or lower

P Carbonate resin

meets ASTM (American Society for Testing and Materials) E-84 standard, fire resistance coefficient 4, smoke degree 1

meets ASTME-841 fire protection standard

Meets NFPANo255 Fire Protection Requirements for Interior Walls and Ceiling Class A standards

Surface treatment safety

The anti-slip performance of the surface must be considered in the design of floor and aisle products, and standard grille products usually use a flat surface design. However, in order to improve the anti-slip performance, on the sloped walkway, the surface is usually covered with an anti-slip layer, that is, the rough sand is implanted into the resin surface.

| G | Grit | With non-slip sand |

| P | Plain | smooth |

Surface treatment / color

A variety of colors are available, we recommend:

polyfiber resin - green vinyl resin - yellow

carbonate resin - reddish brown

G - green

Y - Yellow

D - dark gray

R - red

RB - reddish brown

How to order FRP

*Select the appropriate grille model from the safety load table and deflection table

*Select material, finish and color* If purchasing products from stock, note the grille size

*Normal Grille The clubhead will protrude unless the requested size coincides with the width of the grille

*For other special requirements, please contact our nearest factory or commercial office

| Order listing description | |

| WG 256 IGG | 1/1500 x 1300 span |

| WG 256 VGY | The 2/6250 x 768 span is split into two pieces |

| WG 386 IGG | 6/1220 x 3660 span standard stock board |

Maximum span recommended

Applications under light loads

Used to service the platform in environments that are not used frequently

|

Load grille size(mm) |

Average load = 2.5kPa |

|

|

Deflection = 5mm |

|

25x6 |

850 |

|

38x6 |

1200 |

Light/medium load applications

Platform for less pedestrian light industrial use environments

|

Load grille size(mm) |

Average load = 3kPa |

|

|

Deflection = 5mm |

|

25x6 |

800 |

|

38x6 |

1150 |

Applications under medium loads

General factories and workshops in mining environments, often used

|

Load grille size(mm) |

Average load = 4kPa |

|

|

Deflection two 5mm |

|

25x6 |

750 |

|

38x6 |

1050 |

Product application

| FRP grating safety load and deflection table | |||||||||

| Product model | Grille size | Self-weight kg/m2 | Remuneration load | 450 | 600 | Span(mm) | 900 | 1200 | 4kpa 5mm maximum span |

| U=kpa | 750 | ||||||||

| Deflection mm | |||||||||

| WG256*** | 25x6 | 12.1 | 2.5 | 0.27 | 1.03 | 2.58 | 6.15 | 15.51 | 750mm |

| 3 | 0.33 | 1.25 | 3.1 | 7.6 | 18.61 | ||||

| 4 | 0.44 | 1.67 | 4.48 | 9.64 | |||||

| 5 | 0.55 | 2.37 | 5.17 | 11.97 | |||||

| 7.5 | 0.94 | 3.11 | 7.76 | 17.48 | |||||

| 10 | 1.1 | 4.15 | 10.34 | ||||||

| 15 | 1.74 | 6.23 | 15.52 | ||||||

| WG386*** | 38x6 | 18.6 | 2.5 | 0.1 | 0.27 | 0.98 | 1.68 | 4.7 | 1050mm |

| 3 | 0.12 | 0.32 | 1.4 | 2.03 | 5.64 | ||||

| 4 | 0.17 | 0.43 | 1.71 | 2.7 | 7.52 | ||||

| 5 | 0.21 | 0.53 | 2.02 | 3.38 | 9.4 | ||||

| 7.5 | 0.31 | 0.8 | 2.81 | 5.06 | 14.1 | ||||

| 10 | 0.41 | 1.06 | 3.59 | 6.75 | 18.8 | ||||

| 15 | 0.63 | 1.6 | 5.16 | 10.13 | |||||

Related products

Online Message