Product

Ball joint railing

Ball joint railings have factory production, using ball contact, carbon steel hot-dip zinc or stainless steel production process, with novel and beautiful, easy installation, strong and durable and maintenance-free characteristics.

Keyword:

sheet metal

Category:

Aluminum grille

Product features

Ball joint railings have factory production, using ball contact, carbon steel hot-dip zinc or stainless steel production process, with novel and beautiful, easy installation, strong and durable and maintenance-free characteristics.

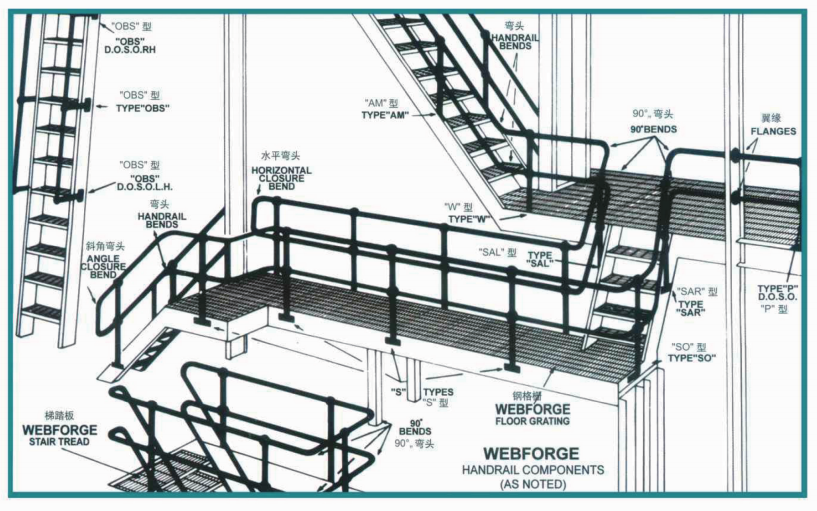

Ball joint railings provide a complete system including columns, handrails, elbows, skirting boards, steel grilles and steppers to meet the various requirements

of customers, thanks to the unique design, ball joint railings are easy to transport and easy to install. For detailed specifications, please refer to this manual, and products can also be made

according to user requirements in accordance with Chinese standard GB4053.3-93, British standard BS6399 and Australian standard AS1657-1992

Product application ball

joint railings are widely used in walkways, platforms, stairs and isolation fences in the fields of mining, electric power, petrochemical, machinery, light industry and shipbuilding, railways, roads, bridges, docks, schools, water plants, sewage treatment plants and gardens.

Naming conventions

Railing model specification sheet

| Model | Number of crossbars | height | Ball diameter | Column diameter | Handrail diameter | Crossbar diameter |

| WHE/1 | 1 | By design | 66 (70) | 42.3(38.1) | 33.5(38.1) | |

| WHS/1 | 1 | By design | 76 ( 85 ) | 48.0(51.0) | 42.3(51.0) | |

| WHE/2 | 2 | 1017 | 66 ( 70) | 42.3(38.1) | 33.5(38.1) | 26.8(32.0) |

| WHS/2 | 2 | 1017 | 76 ( 85 ) | 48.0(51.0) | 42.3(51.0) | 33.5(38.1) |

| WHE/3 | 3 | 1200 | 66 (70) | 42.3(38.1) | 33.5(38.1) | 26.8(32.0) |

| WHS/3 | 3 | 1200 | 76 ( 85 ) | 48.0(51.0) | 423(51.0) | 33.5(38.1) |

Note: * Steel pipe size:

The size of carbon steel is before the parentheses in the above table, and the size of stainless steel is in parentheses. The final design drawings confirmed by both parties shall prevail

* Column spacing: mainly 100012001500mm three.

* Railing height: 1 double: A: horizontal railing: the minimum height of the handrail is 1100mm B: The stairs oblique railing:

the minimum vertical height of the handrail is 900mm

2. Three bars; Usually 1200mm

3, single rod or more than three rod press design

* Connection method between crossbar and column:

1. Generally, the method of welding and fixing is adopted, and local anti-rust treatment is done at the welding position.

2. It can also be fixed with bolts or pins, and the corresponding installation holes need to be drilled on site during installation.

*If the customer reduces the height of the railing, reduces the thickness of the steel pipe or increases the spacing of the column in order to save costs, the company will not be responsible for all the consequences caused thereby

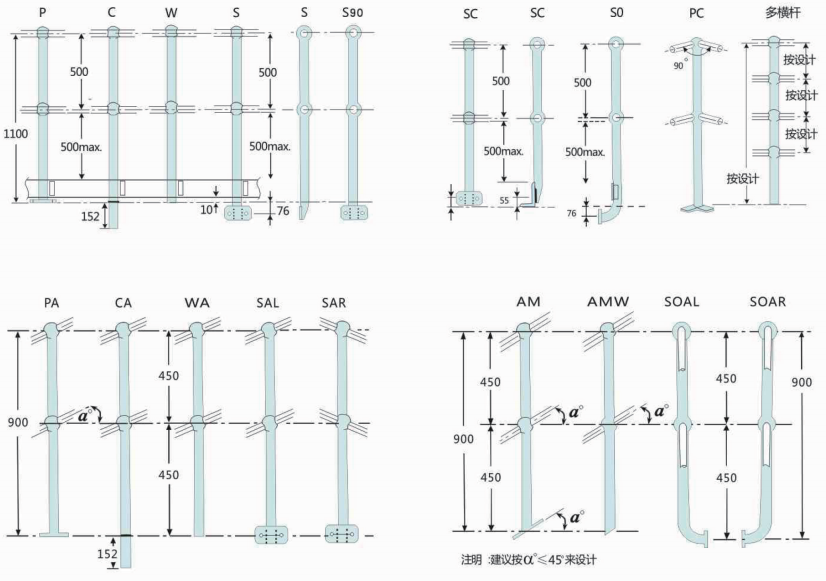

Column form

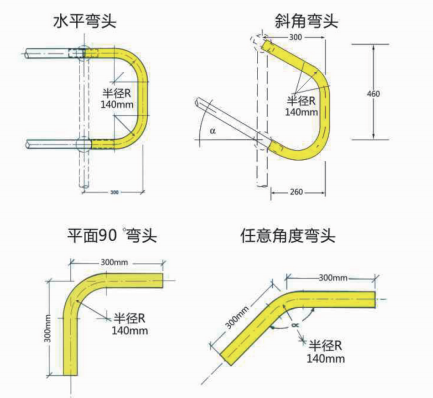

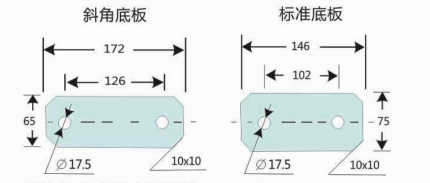

Elbow and base plate form

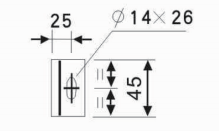

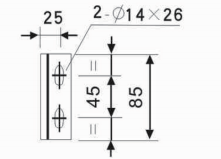

The way the flange is connected to the column

1. Weld directly with the connecting parts on the column.

2. Use bolts to fix with the connecting parts on the column.

(1) Carbon steel with connectors

Angle steel L40X40X5

(2) Stainless steel with connectors

Angle steel L40X40X5

On-site installation

Related products

Online Message